After ten years in the ice cream business, I finally went to ice cream school. What’s even more ironic is I closed my business just months before the course!

I’d always known about Penn State’s Ice Cream Short Course, the school for ice cream manufacturers. In it’s 128th year, it is an intensive week long course, the equivalent of a 15-week 3-credit course, that educates professionals on all aspects of the ice cream industry. It is held in January, the slowest month for business, on the Penn State Campus, with the famous Berkey Creamery serving as a laboratory for research.

Though I owned an ice cream business for ten years, I had never wanted to attend the course before. I regarded it as something geared for large scale manufacturers from whom, and I quote the professor in his opening lecture, “Does it even matter if it’s real ice cream?” Not a course for a purist like me. But at some point in the last couple of years, I decided I should go. Perhaps it had become a bit more applicable for entrepreneurs given the growth in “craft” manufacturers like MilkMade over the years, I thought. But honestly mostly it was to boost my resume. I’d seen some newcomers to the ice cream scene be lauded for “graduating from ice cream school” and, though I knew my ten years of experience to be a far greater education, I wanted to be on level ground. From an outsider’s perspective, at least.

So I enrolled sometime last Spring of 2019 (note that spots in the course sell out very quickly every year, I actually attempted to enroll for last year but was too late), paid my tidy tuition fee, and planned to attend January 2020. Sometime in between, however, I closed MilkMade, seeking a change of pace after ten years in business. Even so, I figured that I’d paid all that money and waited all these years, I should still attend and see what comes of it.

I gotta tell you that I was like some sort of celebrity at this thing. Well, for the half of the class that were entrepreneurs or wanna-be-entrepreneurs. The other half, from big industry, couldn’t give a lick about me. But I had people hailing from all over the country (and world) asking about MilkMade, why I’d closed, what’s next.I kid you not one woman came up to hug me, said she was honored to be in my presence and thanked me for what I’d done for the industry and women entrepreneurs. I had no idea!

During one break someone asked, “So at this point you’re either regretting that you took this course, or you’re regretting that you closed your business.” Neither! I was (and still am) happy with my decision to close MilkMade, AND I was happy to have attended the course.

Here’s what I learned:

In the first day, everyone is asked to introduce themselves and tell the group what is their “ice cream dream.” Again, half of the class came from big business: Unilever, Froneri, Kemps, and the like. Their dreams were mostly around quality control or perhaps finally getting one of their ideas to market. The other half were small businesses or people who wanted to start small businesses. Of course, the dream of all of those entrepreneurs was to become one of the big guys, a large global brand. And then there were a select few from my favorite group, family run dairy farms. Huge admiration.

Once niceties were out of the way, we dove right into learning a scientific foundation for ice cream. In his opening remarks, the professor noted that ice cream is easy to make. When it works, at least, it’s easy. But when it doesn’t work, you need to know the science. I agree, but would add that if you innovate, which is what MilkMade was known for, you also need to know the science.

When I started MilkMade, I taught myself a basic understanding of the chemistry of ice cream, enough that I could create recipes from scratch and iterate on them until they tasted just right. Famously, it took me ten tries to develop my Red Velvet Cake cheesecake ice cream base when I first started out. But more than just testing the ratios of fat to milk solids to sugars, this course provided a much more in depth venture into, say, how the fat molecules in an ice cream mix get protected by a protein, which allows it to partially coalesce during the ageing process in order to trap air more easily during the freezing process. Fascinating, really.

The lectures were 1-1.5 hours and covered everything – the composition of milk, different types of sweeteners and stabilizers, food microbiology and pathogen control, current regulatory guidelines, how to market, how to calculate an ice cream recipe, and of course, how exactly to make ice cream.

The majority of the course is in lecture form, with a few hours each day dedicated to the lab at the Berkey Creamery. In lab, we had a tour of the creamery, a demonstration of different types of batch freezers (code for small ice cream machines), and a taste-test of all different types of vanilla extracts. In my favorite lab, we explored the differences that different variables of ice cream – overrun, milkfat and milk solids content, and stabilizers – have on the final product. These differences were stark and really eye opening for me, though require a lengthier description in perhaps a later post. Needless to say, my preferred ice cream profile was low overrun (that’s the amount of air whipped in during the freezing process), high milkfat (that’s exactly what it sounds like), and no stabilizer (a gum, syrup, or starch meant to reduce ice crystal growth).

I wasn’t much for networking during the course (my breaks and meal-times were spent pumping breastmilk for my 1 year old at home), but I did glean some interesting secrets from others in the industry. In a side conversation with a fellow from one of the big manufacturers I was asked, “What do you do with mistakes?”

“Throw them away,” I said. “What do you do?”

“Turn it into chocolate.” He went on to tell me how they turn all their seconds into chocolate. For example, if a container of Neapolitan turned out with unequal amounts of strawberry, vanilla, and chocolate ice creams, they’d melt the whole thing down, add in some other flavorings and turn it all into chocolate.

“See, you’re why I started my business in the first place,” I told him.

A few other anecdotes from the course reminded me just why I had started MilkMade. The discussion of flavorings, assuming “jug” flavorings were the common way to create ice cream flavors. That means using a jug of strawberry flavored syrup instead of real strawberries.

A question from the audience about the use of eggs instead of gums or syrups as a stabilizer. It was pretty much dismissed by the lecturer. (MilkMade used eggs in most ice cream bases.)

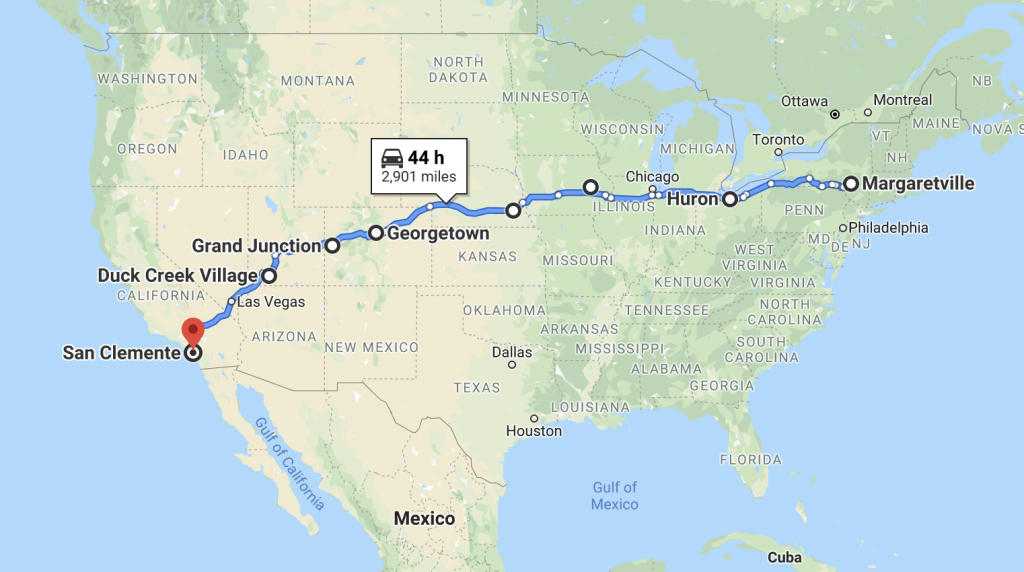

One lecturer discussed how common it is that the trucks transporting ice cream across the country turn off the cooling system once they leave the warehouse and turn it back on before getting to their destination checkpoint. This is done to save money on refrigeration of course, causing the ice cream inside to melt and refreeze unnoticed at the checkpoints. To avoid this, companies use alarms on their pallets to signal the rise above a certain temperature. They also inject a cocktail of stabilizers to ensure a “shelf stable” product despite temperature fluctuations involved in distribution.

This all made me think that ice cream isn’t meant for national distribution. It’s not meant to be transported on a truck cross country to then sit on a loading dock waiting to be stocked. It’s not meant to sit on a supermarket shelf for a year. And it shouldn’t need a cocktail of gums to survive. I’ve always believed in this; it’s why I got started making ice cream in the first place and it is how we operated at MilkMade. (Note that we did test out our own shipping direct-to-consumer, and because we didn’t change our manufacturing process to do so, the operations proved to be too costly so we re-focused on local delivery instead).

Anecdotally, there used to be an ice cream store in every town. Over time, manufacturing consolidated, price wars were waged, and the quality of the product deteriorated. Of course, over time there have been renaissances of novel premiums products. Breyers in the late 1800s. Dryer’s/Edy’s in the 1920s. Haagen Dazs in 1960s. Ben and Jerry’s in the late 70s. Milkmade in 2009 (hehe). But, like the “ice cream dreams” of all of the entrepreneurs in my class (which, by the way, is the same dream that I used to harbor for MilkMade), they became big, global brands. And with that, the quality of their ice cream deteriorated.

At some point in the past ten years since starting MilkMade, I realized that my desire to build a big business and my commitment to the unique quality of my product could never align. So we doubled down on the latter, dialing up what made MilkMade so unique – quality ingredients sourced locally, small batch production, and a rotating menu of creative flavors.

Though for all the trolling I’ve done to large scale manufacturers, I will say that after attending the course I have a new found admiration for the science (and obviously operations) that goes into the production of large scale commercial ice cream. It’s remarkable.

Long story short – I’ve been asked if I would recommend the Penn State Ice Cream Short Course to aspiring entrepreneurs. I most definitely would.